Lehigh University

The Tribology Laboratory at Lehigh University

Facilities

Facilities, Equipment and Other Resources

Laboratory

Primary laboratory space in Packard laboratory at the P. C. Rossin College of Engineering and Applied Science at Lehigh University. Laboratory contains tribometers for measuring friction and wear of composites. Also Laboratory space includes a class 10,000 cleanroom as well as exhaust hood for ventilation.

Tribometers:

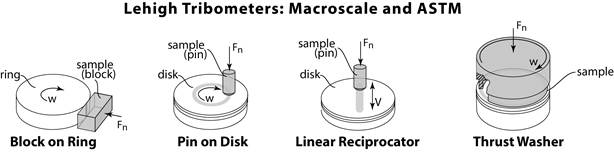

Macroscale:

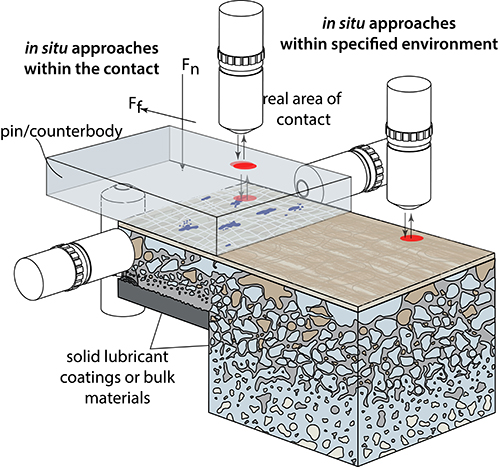

Linear Reciprocating Tribometer

This is a custom, student-built instrument for measuring friction and wear of polymer composites (and other materials). This instrument is an extremely capable and flexible tool to evaluate tribological contacts at loads from 50 to 1000+ N at application relevant sliding speeds (<0.1 to >250 mm/s) and temperatures easily above 200 ºC (400 ºF). The open platform design allows access for a variety of additional experiment features, including lubricant application and temperature control. This instrument can be housed in an environmentally enclosed glove box to explore the effects of various background gasses, including humid air at various humidity levels. Loading geometries include flat-on-flat, ball (hemisphere)-on-flat, point-on-flat (cone, pyramid or corner), and cylinder-on-flat (line contact) can all be applied for a range of contact pressures. Custom instruments allow for extreme experimental flexibility and control.

Thrustwasher Tribometer

A custom thrustwasher tribometer is currently in the design phase and will be built by the beginning of this project. This instrument is capable of multiple ASTM standards as well as a variety of custom experiments. It also has an extended history in use in benchmarking materials for various companies and industries with a wealth of practical experimental applications. The thrustwasher can perform a variety of experimental conditions, including a 10 to 1,000 N normal load and 25 to 4200 RPM sliding rotational velocities. The current custom design at Lehigh allows for additional flexibility, including increased load ranges, speed ranges, varied lubrication strategies and environmental control due to a modular construction scheme. This instrument is capable of temperatures above 200 ºC (400 ºF). Contact geometries include typical mated concentric washers as well as flat-on-flat geometries.

Block on Ring Tribometer

A custom block on ring tribometer is currently in the design phase and will be built by the beginning of this project. This instrument is capable of multiple ASTM standards as well as a variety of custom experiments. It is representative of bushing and bearing applications. It has an extended history in use in benchmarking materials for various companies and industries and is imperative for industrial translation of the materials and research. The block-on-ring is a good instrument for performing a variety of experimental conditions, including a 5 to 1,000 N normal load and <15 mm/s to >1,000 mm/s sliding velocities. The current custom design at Lehigh allows for additional flexibility, including increased load ranges, speed ranges, varied lubrication strategies and environmental control due to a modular construction scheme. This instrument is capable of temperatures above 200 ºC (400 ºF). Contact geometries include typical block/pin-on-ring, ball-on-ring and conformal block on ring.

Pin on disk Tribometer

A custom pin on disk tribometer is currently in the design phase and will be built by the beginning of this project. This instrument is also capable of multiple ASTM standards and custom experiments. Pin on disk tribometers have been utilized in many areas of research such as coatings, electrical contacts and bio-inspired systems. Industries have utilized this tribometer in conjunction with previously mentioned ones for benchmarking and testing materials. The pin-on-disk tribometer can cover numerous experimental conditions with a 1 to 1,000 N normal load and <15 mm/s to 1,000 mm/s sliding velocities. This is capable due to the instruments flexibility in easily changing configurations to accommodate different load applying techniques as well as ge aring for speed ranges, various lubrication regimes and environmental control. The instrument is capable of temperatures above 200 ºC (400 ºF).

Microscale

Microtribometer

The microtribometer (called a nanotribometer by most tribometer companies) can reveal interesting phenomena at very small force and length-scales. Our student-built instrument is capable of load resolutions < 1 µN to load capacities greater than 1 N (depending on the custom-built cantilever design) and position resolutions of 0.5 nm. Loading geometries of this tribometer also include flat-on-flat, ball (hemisphere)-on-flat, point-on-flat (cone, pyramid or corner), and cylinder-on-flat (line contact) can all be applied for a range of contact pressures. Configurations of this instrument are capable of sliding geometries ranging from linear reciprocating to rotating pin on disk as well as in situ observation of wear with an optical profilometer. Sliding velocities range from less than 1 µm/s to several mm/s. This instrument is capable of temperatures above 200 ºC (400 ºF).

We currently have 2 microtribometers. One is housed in glove box.

In situ reciprocating pin on flat Minitribometer

Linear tribometer with flexible load ranging from <0.1 to >10N. Can be housed in one of the glove boxes for environmental control. Also capable of in situ wear scar topography measurement with the scanning white light interferometer

Rotary tribometer

Rotary tribometer with flexible load ranging from <0.1 to >10N. Can be housed in one of the glove boxes for environmental control. Also capable of in situ wear scar topography measurement with the scanning white light interferometer

Glovebox

- Standard lab glove box capable of <1 ppm O2 and H2O. Tribometers fit inside.

- Custom glovebox for “dirty” environments

Scanning White Light Interferometer - Surface Topography and Wear Quantification

One of our primary tools to characterize a surfaces roughness as well as the amount of material removed during wear is an optical profilometer. Bruker GT-k1 scanning white light interferometer. It has nearly every option, including 5X, 10X, 20X and 50X objectives, 0.5X, 1X and 2X multiplier, and automated stages for stitching and measurement automation. It can make accurate surface topography (as low as 0.1nm z resolution) as well as wear profile measurements.

Mettler Toledo XS 205 Digital Scale

The XS 205 has a resolution of 0.01 mg for accurate mass based wear measurements of ultra-low wear polymer composites.

CNC milling machine for sample preparation

Lehigh has a CNC milling machine in the laboratory to machine samples as well as customize instrument components.

Materials Synthesis

Polymer composites

We have complete suite of tools for powder metallurgy-based processing of polymer composites, including composites of polytetrafluoroethylene (PTFE), polyether ether ketone (PEEK) and other high-performance, high-temperature engineering polymers.

Atomic Layer Deposition (ALD)

Collaborator Nicholas Strandwitz has multiple deposition systems. See his website (http://strand.web.lehigh.edu) and facilities page (http://strand.web.lehigh.edu/content/equipment) for more info.

MOCVD

Collaborator Nelson Tansu is director of the Center for Photonics and Nanoelectronics, which has a VEECO P-75 GaN based MOCVD Reactor for AllnGaN materials and a VEECO D-125 GaAs/InP based MOCVD Reactor. See http://www.lehigh.edu/~incpn/research/facilities/mocvd.html

Other Characterization Facilities Available

Surface Analysis

XPS –Scienta ESCA-300

The Scienta ESCA-300 is a high Resolution-X-ray Photoelectron Spectrometer (HR-XPS) system. The sample chamber and/or attached chambers provide the ability to heat specimens to >1000°C without the use of electron bombardment, expose surfaces to various vacuum compatible reactant gases, deposit thin films from a precision Knudsen cell and monitor the thickness with a crystal monitor, monitor the vacuum with an RGA, fracture brittle samples in situ, sputter clean surfaces, and scrape surfaces in UHV. The sample entry chamber, which can have base pressures in the low 10 -8 torr range, can be used to carry out experiments at temperatures >400°C at pressures ranging from 10 -8 to 700 torr.

HS-LEIS: High Sensitivity Low Energy Ion Scattering (Qtac 100)

The only system of its kind in America, the new Qtac 100 High Sensitivity-Low Energy Ion Scattering (HS-LEIS) spectrometer system, complete with in situ pretreatment chambers. This new machine utilizes a unique double toroidal electrostatic energy analyzer that provides 3,000 times higher sensitivity than conventional ion scattering spectrometers. The Qtac100 is has been developed to include small spot analysis, surface imaging, and static and dynamic depth profiling, as well as 3000 times higher sensitivy than conventional LEIS instruments. This instrument provides the best quantitative look at the top atomic layer of materials and is truly sensitive to the first atomic layer.

Materials Characterization

Raman Microscope – Alpha 300 RA

The well-established Raman-AFM combination alpha300 RA was the first integrated Raman AFM system on the market and continues to set the standard for combined instrument configurations for correlative Raman-AFM microscopy. The alpha300 RA incorporates the features of the Raman microscopy system alpha300 R for powerful chemical imaging along with Atomic Force Microscopy (alpha300 A) for high-resolution nanoscale surface characterization. Thus correlative Raman AFM imaging facilitates a comprehensive understanding of the samples.

With the alpha300 RA the two complementary imaging techniques are available in a single instrument without compromise and are controlled by one software suite for the highest ease-of-use and reliability. Switching between the imaging techniques requires just a turn of the objective turret, with all imaging parameters automatically adjusted and the same sample area easily imaged with both techniques. The software also allows the effortless correlation of the Raman and AFM results and the image overlay.

The alpha300 RA is furthermore ideally suited fo TERS (high-resolution Raman) AFM measurements.

Spatial resolution (laser spot size) ~800nm. 25mm travel range, 532 and 785 laser lines, motorized sample positioning and measuring with piezo-driven scan stages.

XRD: Panalytical Empyrean X-Ray Diffraction System

Purchased in 2016, a highly versatile diffraction tool capable of measuring powders, bulk solids, and thin films. Available for internal and external/industrial users. Three incident beam optics include a Bragg Brentano HD mirror, a hybrid 2-bounce Ge monochromator, and a fixed slit holder. Diffracted beam optics include a fixed slit holder and parallel plate collimator (for grazing incidence XRD, GiXRD, and X-ray reflectivity, XRR). Pixcel 3D area detector enables ultrafast measurements. DHS 1100 heated stage enables in situ heating up to 1100 °C in inert atmosphere, air, or vacuum. Several software packages available including Highscore (powder analysis), Epitaxy, and Stress.

Lehigh Electron Microscopy Facility (UPDATE)

Lehigh Electron Microscopy facility has Transmission Electron Microscopes (JEOL JEM-1200EX, JEOL JEM-2000FX, JEOL JEM-ARM200CF), Scanning Electron Microscopes (FEI XL30 ESEM, Hitachi 4300 SE/N, JEOL JSM-840, JEOL JSM-6400CL (cathodoluminescence), JEOL JXA-8900, ZEISS 1550), and Focused Ion Beam Equipment (FEI Scios DualBeam)

Selected instruments description

TEM (JEOL JEM-ARM200CF)

The ARM200CF is an atomic resolution transmission electron microscope operating at a maximum accelerating potential of 200kV that features a cold field emission source. A third-order aberration corrector near the sample allows higher beam currents to be focused into smaller probe sizes than ever before at Lehigh. A new design of X-ray detector allows collection of spectroscopic chemical analysis data with higher sensitivity and efficiency than any other system available. The whole system is tuned for operation at three accelerating potentials, allowing a wider range of materials to be examined with atomic level resolution. In the near future a new generation energy-loss spectrometer and imaging filter will be added to complete the arsenal of analytical techniques on offer.

SEM (Hitachi 4300 SE/N)

The Hitachi 4300SE/N is an analytical high resolution (1.5nm/30kV) variable pressure Schottky field emission SEM (VP-FESEM). This SEM is equipped with a light element energy dispersive X-ray analyzer (EDS) and electron backscatter diffraction (EBSD) camera. Additional electron imaging modes include backscatter (BSE), gaseous secondary (GSE), forward scatter (FSE), and scanning transmission (STEM).

SEM (ZEISS 1550)

The Zeiss 1550 is a high resolution (2nm) variable pressure FESEM. It’s unique Gemini column combined with an in-lens detector make it ideal for imaging soft materials at extremely high magnifications. The 1550 also features a Nabity Nanometer Pattern Generation System (NPGS) for doing advanced electron beam lithography.

FIB (FEI SCIOS DUALBEAM)

Scios DualBeam delivers outstanding 2D and 3D performance for a broad range of materials, including metals, composites, and coatings. Scios performs high-resolution, high-contrast imaging, even on magnetic samples. Scios simultaneously detects material, topographic, and edge contrast to analyze full material properties, and it creates site-specific cross sections without preparation, even on non-conductive materials. Innovative features allow FEI's Scios DualBeam to generate 3D data cubes to determine the size and distribution of inclusions in a metal or to analyze the stress and strain around a crack tip in all directions. In addition, you can use Scios to rapidly and reliably prepare high-quality samples for S/TEM, EBSD, or atom probe applications.

Advanced detection technology is at the very core of the FEI Scios. In-lens FEI Trinity detection technology collects all signals simultaneously, saving time and offering distinctly different contrasts to capture the maximum amount of data. An innovative, under-the-lens concentric backscatter detector enhances efficiency, enabling you to select a signal based on its angular distribution to easily separate materials and topographic contrast - even at 20 eV landing energy.

Center for Advanced Materials and Nanotechnology (CAMN)

http://www.lehigh.edu/nano/

The Nanocharacterization Laboratory at Lehigh contains one of the largest electron microscopy facilities in the U.S., with a suite of 10 scanning, transmission and scanning / transmission instruments. These are well suited for characterizing nanoscale structures and chemistry via an unparalleled range of imaging and analytical methods. The Electron Microscopy Facility has support services to keep the instruments at peak performance and to optimize their use. There are complete specimen preparation facilities including a Gatan PIPS, a plasma cleaner, chemical jet polishers, dimplers, wire saws, diamond cutting wheels and a comprehensive metallographic suite. In addition, there are facilities for digital image acquisition and manipulation, off-line computers for data analysis, and extensive microscopy-related software. Modifications to the instruments can be developed with the aid of a machine shop, which is nearby.

Light Optical Microscopy

Light Optical Microscopy is also available at CAMN with Nikon Microscope (to 1000X, Bright field/Dark Field/Polarized Light), Zeiss Metallograph (to 1500X, Bright field/Dark Field/Polarized and Oblique Light), Reichert Metallograph(to 1500X, Bright field/Dark Field/Polarized Light; Normarski Diffraction Interference Contrast) and an Olympus Hot Stage Microscope (Heating to 1500 C; Video Imaging).

Nano-Mechanical Behavior

Lehigh has an in situ SEM Hysitron PI-85 Picoindenter: Simultaneous high resolution imaging and indentation, compression, bending, or tension. This can be combined with Lehigh’s focus ion beam milling facility to prepare specimens for nanomechanical testing.

Lehigh also has a nanoindenter (Hysitron Triboscope on DI small sample AFM) for nanoindentation and nanoscratch measurements.

Atomic Force Microscopes at Lehigh User facilities

Digital Instruments 3000: Vertical range: 5 nm – 5 μm, Horizontal range: 1 μm – 100 μm square, Fluid cells, Contact, Tapping Mode, STM

NT-MDT Solver NEXT: Numerous AFM and SPM modes

NT-MDT NTEGRA Invert on Olympus IX-71 optical microscope

Center for Photonics and Nanoelectronics

http://www.lehigh.edu/~incpn/

CPN houses:

INTEGRATED NANOFABRICATION & CLEANROOM

The Integrated Nanofabrication and Cleanroom Facility (INCF) supports research and developments in microfabrication techniques, and device fabrications.

http://www.lehigh.edu/~incpn/research/facilities/incf.html

MOCVD EPITAXY & SYNTHESIS

Lehigh University's Smith Laboratory facility supports research in the fields of semiconductor nanostructure, semiconductor optoelectronics, photonics integrated circuits, and III-Nitride and III-V semiconductor devices.

http://www.lehigh.edu/~incpn/research/facilities/mocvd.html

OPTICAL / DEVICES / SYSTEMS CHARACTERIZATION FACILITY

Extensive material characterization facilities are available to support such operations as Hall measurements, optical reflectance, photoluminescence mapping, x-ray diffractometering, atomic force microscopy, confocal and scanning near-field optical microscopy.

http://www.lehigh.edu/~incpn/research/facilities/dscf/

Resources for outreach: k-12 tribology experiments: PI co-built and shares the following educational resources with the University of Florida, University of Delaware and University of Illinois.

- “Tootsie Pop: How Many Licks Does It Take?” – this equipment includes a dozen scales for measuring the mass of a tootsie pop for a class full of students as well as one portable scanner.

- “Leonardo da Vinci’s Science Friction” – a reproduction of da Vinci’s tribometer

- “Strong Man Sled Drag – Can you build a pyramid?” – A sled experiment that lets students explore pulling a 100 kg stone slab, using various sliding materials.

K-12 education resources: (Top) 3d- scanner for experiment 1. (bottom left) reproduction of da Vinci’s tribometer for experiment 2. (bottom right) instrumented stone sled for experiment 3.

I will periodically update progress of the laboratory and capabilities.

The main laboratory is located in Lehigh's Packard Laboratory.

Other Resources

Surface characterization is imperative to research in tribology. The Tribology Laboratory is conveniently located near Lehigh's Center for Advanced Materials and Nanotechnology. This center includes Lehigh's renowned electron microscopy facility amoung other facilities.