Lehigh University

P.C. Rossin College of Engineering and Applied Science

Materials Research for Fossil Energy: Corrosion

CORROSION

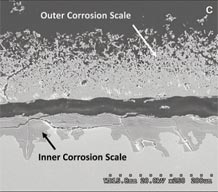

Environment regulations have required coal fired power plants to reduce the amount of NOx emissions produced by the coal combustion process. This has prompted the use of low NOx boilers which utilize a stage combustion process to create reducing conditions within the boiler. This has resulted in severe wastage of the waterwall tubes due to the highly corrosive sulfidizing gases in the boiler environment and significantly shortened the lifetimes of the waterwall tubes. Ni-based weld overlays are used to alleviate this issue. However, they are often susceptible to premature failure due to corrosion fatigue cracking. The cracking eventually leads to the failure of the waterwall tubes and requires forced outages to make the necessary repairs. From a materials view point, susceptibility of weld overlays to corrosion fatigue is due mainly to the localized melting and re-solidification of the weld overlay process. This results in microsegregation which depletes the dendrite cores of critical alloying elements and results in preferential corrosive attack. In addition, the overall alloy content of the weld overlay is reduced due to dilution with the low alloy steel. The high residual stresses from the weld overlay process also exacerbate the corrosion fatigue problem. As such, there is a need to develop coating technologies that avoid these issues. The solid state process of coextruded coatings provides a potential solution because it does not involve localized melting and re-solidification.

Corrosion tests have demonstrated that Ni-based coextruded claddings provide significantly better gaseous and solid state corrosion resistance than the weld overlay coatings. This is attributed to elimination of dilution and microsegregation in the coextruded coating. A corrosion fatigue testing technique was developed to characterize the corrosion fatigue resistance of the claddings using a Gleeble thermo-mechanical simulator. The results have demonstrated that the testing technique accurately simulates the corrosion fatigue mechanism of Ni-based weld overlays in service. Currently the corrosion fatigue behavior of Alloy 622 GMAW weld overlay, laser weld overlay and coextruded cladding are being evaluated.

Publications:

- DuPont JN, Stockdale AW, Caizza A, and Esposito A. 2013. High-temperature corrosion behavior of alloy 600 and 622 weld cladding and coextruded coatings. Welding Journal (July): 218s-224s.