CCUS - Carbon Capture, Utilization, and Sequestration

Project 1. Carbon mineralization

Collaborating with Steve Peters (EES), Carlos Romero and Sudhakar

Neti (Lehigh

Energy Resarch Center), Muhannad Suleiman, Paolo Bocchini,

Clay Naito (CEE),

Jonas Baltrusaitis (ChemE),

Karen Beck-Pooley (PolySci), and Alberto Lamadrid (Econ).

Once CO2 is captured and concentrated it needs

to be safely sequestered in geologic reservoirs over geologic time

scales. The traditional way of doing this is by injection

into deep saline aquifers or in permeable, former hydrocarbon

reservoirs; however, there are geographic and geologic barriers to

doing this in eastern Pennsylvania. Here we will investigate

a relatively novel solution consisting of direct back-to-rock CO2

mineralization, using Ca- and Mg-rich waste rock from the

aggregate mining industry. This sequestration option, which takes

advantage of the natural silicate weathering cycle, has the

potential to remove MtCO2/yr from the atmosphere, a

flux that scales well with the current emissions of the

Pennsylvania cement industry. Although Pennsylvania has the

correct rock mineralogy and distribution to justify our enthusiasm

(Fig. 1a), significant knowledge gaps in reaction rates, and

comparative texture and mineralogy of the waste stream

mineralizing the carbon remain. Research projects need to

specifically target the reaction rate problem, focusing on the

grain size (reaction surface area) and mineralogy of the aggregate

waste stream, with an eye on favorable energy conversion processes

that may lead to desirable by-products (Fig. 1b).

We

have reason to be optimistic that diabase and serpentinite waste

generated by the aggregate industry in eastern Pennsylvania is an

excellent material for mineralizing CO2. The

chemistry involves Mg and Ca-rich silicate minerals.

Consider the silicate mineral diopside, which occurs in

diabase aggregate waste at ~30 wt%, to illustrate the process:

MgCaSi2O6 + 2CO2 +

4H2O = MgCO3 (solid)+ CaCO3

(solid)+ 2H4SiO4 (aqueous)

(3)

For every 2 moles of CO2 (44 g/mole; 88 g), the

dissolution of diopside consumes 1 mole of pyroxene (216

g/mole). That is one needs 216 g of rock waste (assuming it

was pure diopside) to neutralize 88 g of CO2, or ~2.5 g

of rock for every 1 g of CO2. For example, the

Pennsylvania cement industry is emitting ~1.8 MtCO2/yr,

which translates to ~5,000,000 m3 of rock at 30 wt%,

diopside to effectively mineralize all of this carbon.

However, diopside is paired with other silicate minerals like

labradorite feldspar, which also dissolves congruently and

consumes CO2, so the necessary rock waste volumes would

be less. Furthermore, even considering the modest known reaction

rates of ~10-11 moles/m2/s, the dissolution

of the Mg- or Ca-rich silicate proceeds over time frames of years

to tens of years. The resulting bicarbonate ion remains in

the Earth surface system for decades to centuries, and the final

natural mineralization takes place over centuries. All of

these are time frames commensurate with what is necessary to

remove anthropogenic CO2 from the atmosphere.

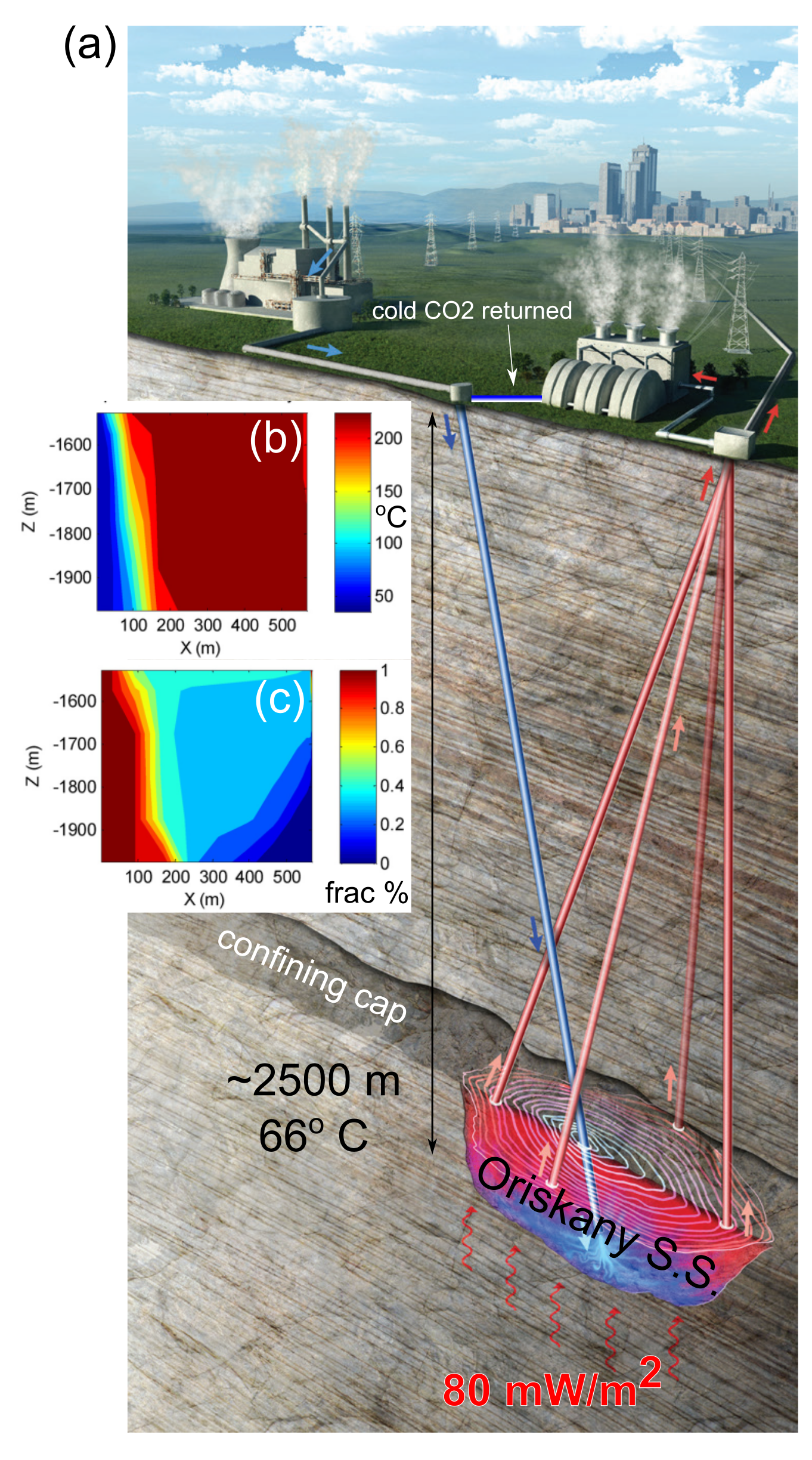

Figure

1. (a) Geologic map of east-central and southeastern PA

showing the close geographic distribution of the cement

industry to the north of Lehigh, and the location of the rocks

south of Lehigh where aggregate waste capable of mineralizing

the CO2 are located. (b) Summary diagram

showing the production of favorable by-products possible in

the CO2 mineralization process from: Gadikota, G.,

2021, Carbon mineralization pathways for carbon capture,

storage, and utilization: Nature Communications Chemistry,

4-23, doi.org/10.1038/s42004-021-00461-x.

Project 2. Carbon sequestration and low-enthalpy geothermal energy.

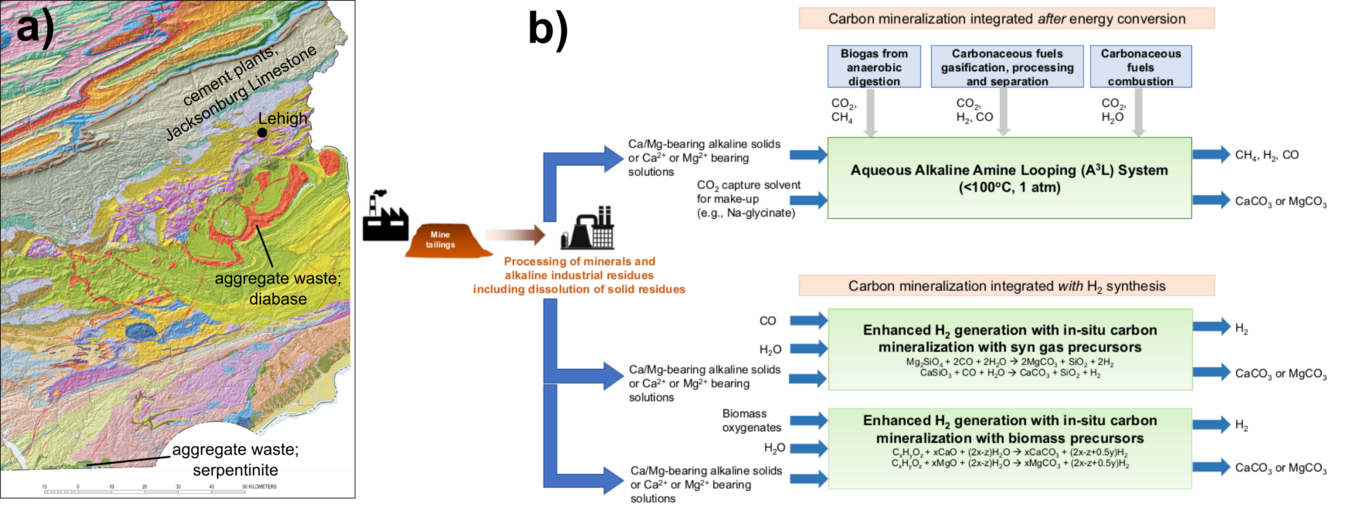

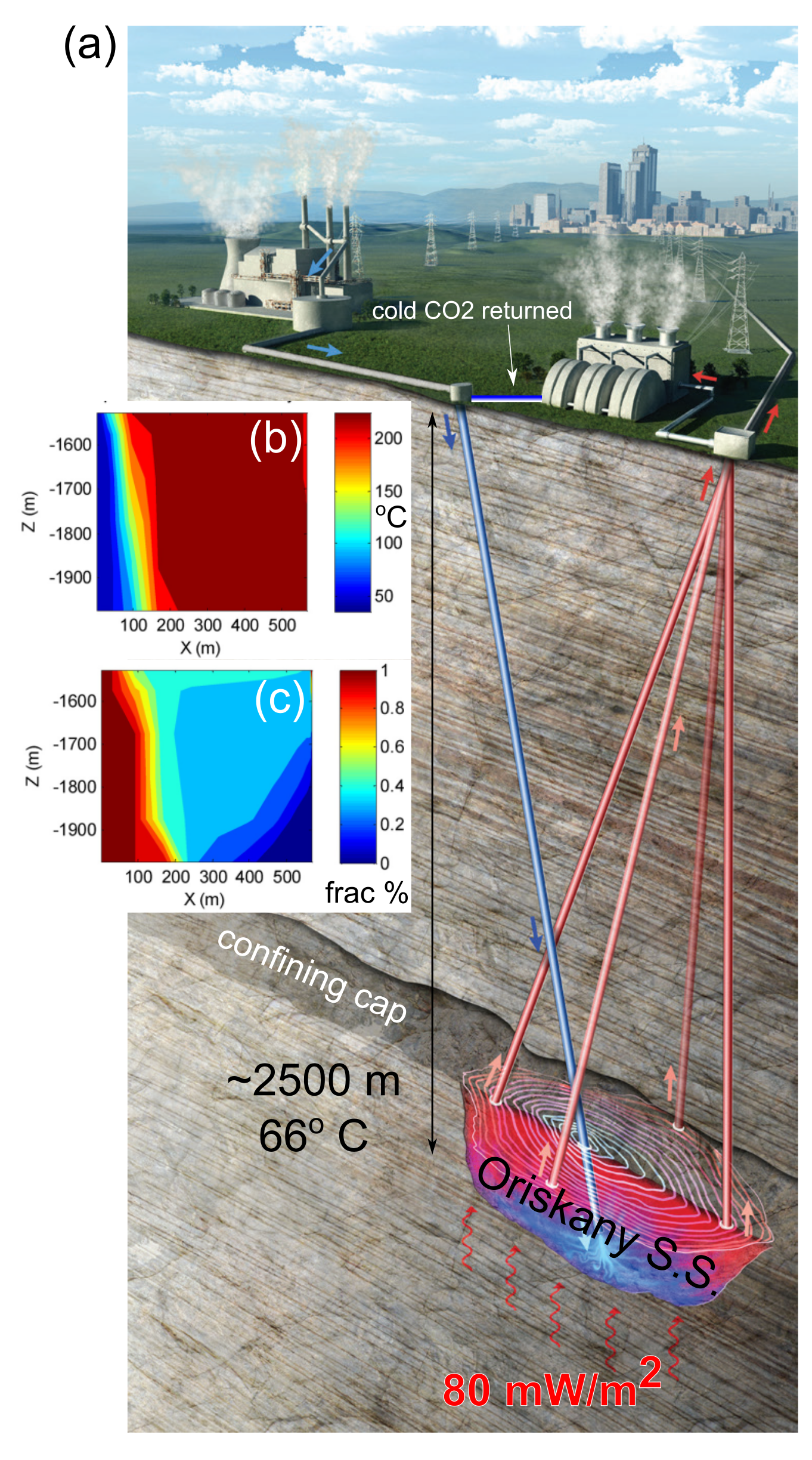

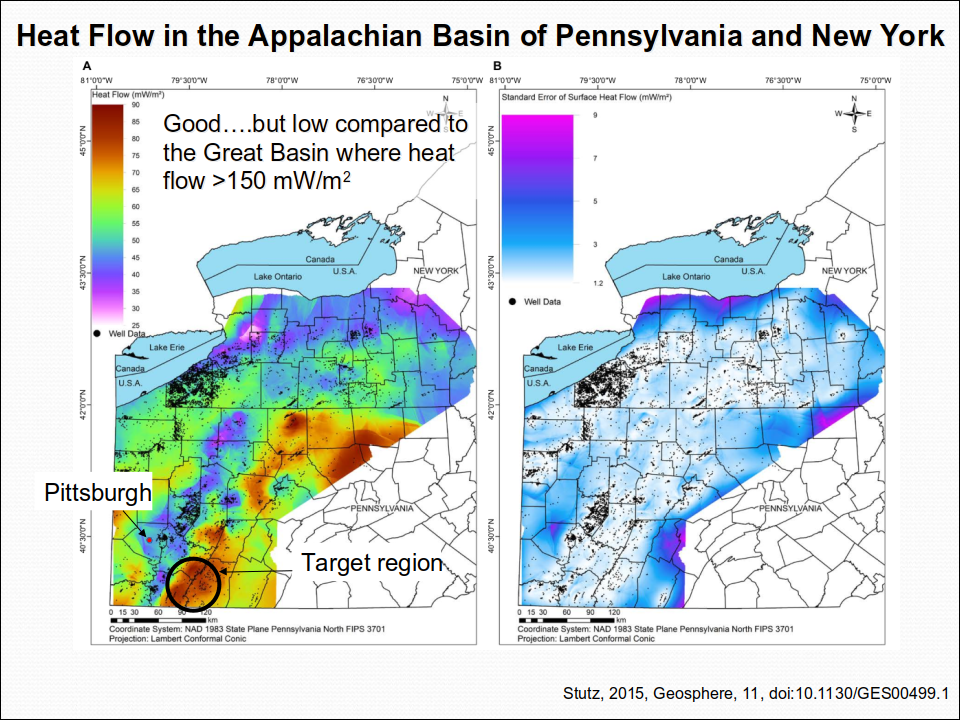

We are researching power generation and/or district heating using a novel super-critical CO2 (sCO2) injection technology that leverages an existing network of CO2 sources and deep wells to harvest energy from a relatively untapped geothermal energy resource proximal to major population centers with growing energy needs (Fig. 1). Unlike traditional geothermal projects that target shallow, hot, dry rock, typically using water or steam, and involve the drilling of new wells, the novelty in our concept emerges from the nexus of: (1) utilization of sCO2 injection to extract large quantities of low-exergy heat, (2) re-purposing existing, suitable hydrocarbon wells, (3) mining heat from an anomalously warm part of the Appalachian Basin (Stutz et al., 2015; Fig. 2), and (4) realizing an associated benefit of partial CO2 storage. This multi-phase project aims to generate power from a comparatively low-temperature geothermal source, demonstrating its potential when it is scaled and applied to warmer sources elsewhere in the country.

Fig. 1. (a) Illustration of our concept for extracting geothermal heat using sCO2 from a conventional natural gas reservoir in the Appalachian Basin, in this case shown as the Oriskany Sandstone, which is already penetrated by existing wells. Observation-based modeling results from the Lehigh group showing (b) geothermal reservoir temperature and (c) percent sCO2 saturation after 5 years for comparable depths and distances between the injection and production wells proposed for this project (modified from Pan et al., 2018).

Figure 2. A Heat flow and B standard error in heat flow calculation for the Appalachian Basin in Pennsylvania and New York. (Stutz et al., 2015, Geosphere, 11, doi:10.1130/GES00499.1).